Customizable Deliverables

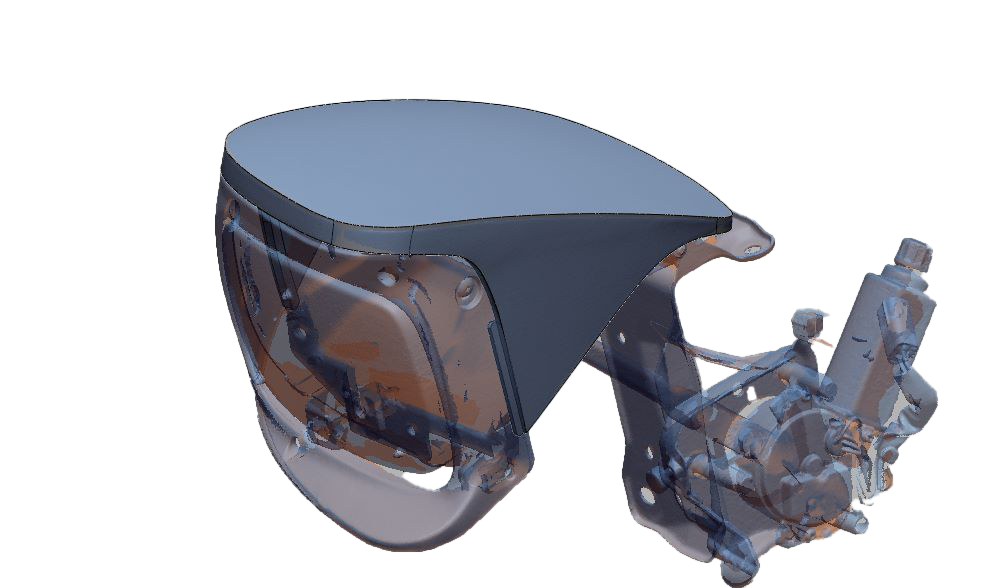

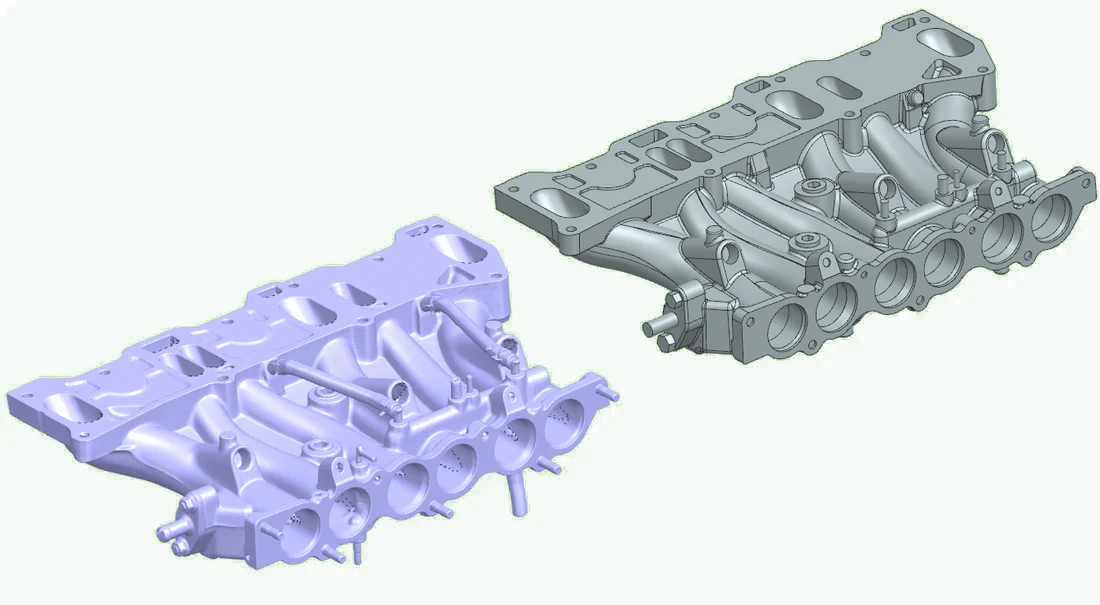

Once scanning and data processing are complete, we deliver your digital files in the format that best fits your workflow. Our standard deliverables include high-quality mesh files (.STL / .OBJ). To help you move quickly, we also include complimentary reverse engineering of select basic features—such as planes, hole locations, and reference geometry.

For projects requiring deeper design intent, we offer full reverse engineering services, providing a complete parametric reconstruction and delivery of a .STEP file. This approach gives you full flexibility and control to use your data for product development, inspection, quality, or downstream manufacturing applications.

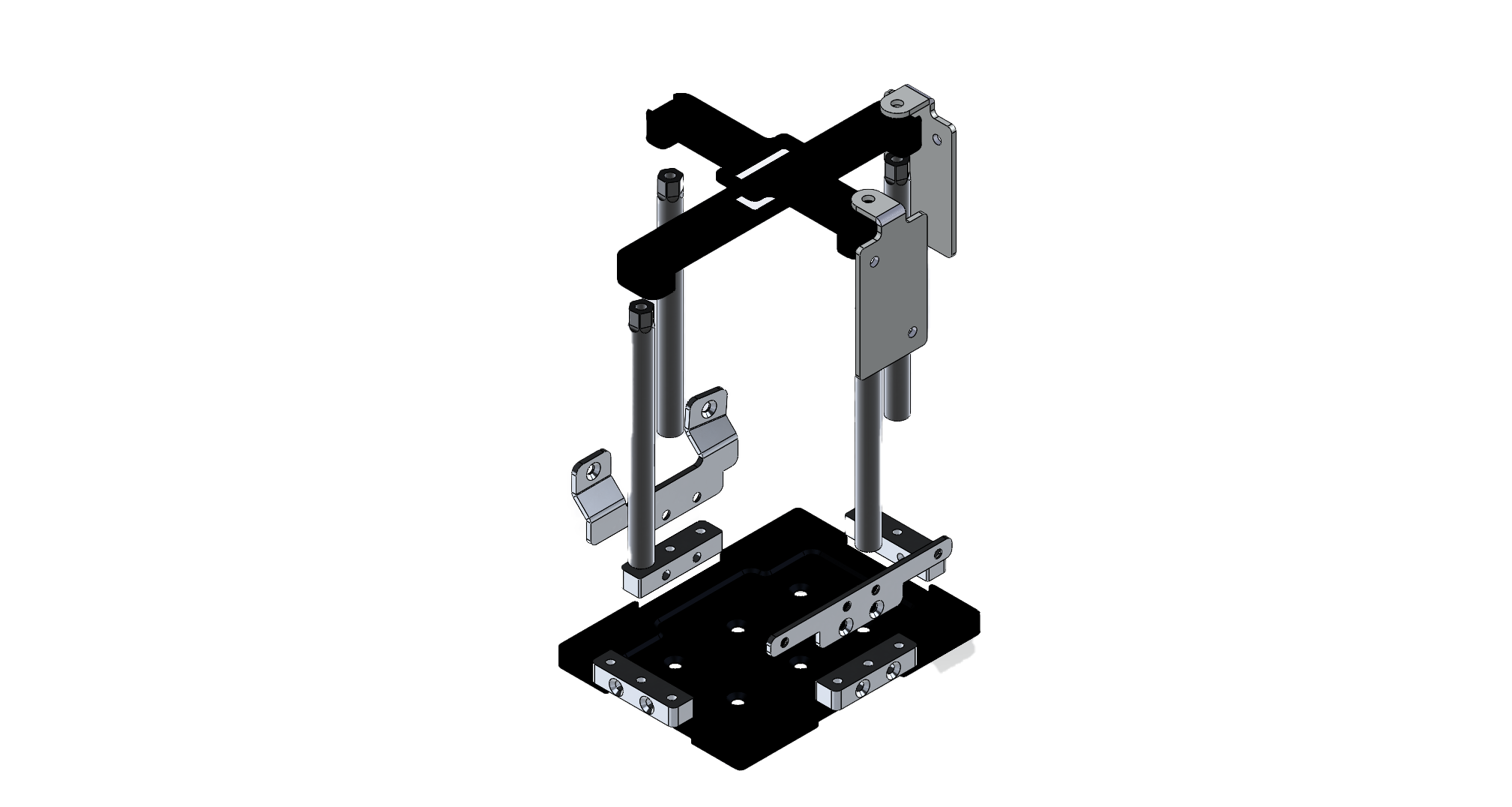

Turnkey Engineering Design Services

For clients seeking a complete, end-to-end solution, we offer turnkey engineering design services that span the entire engineering lifecycle. From initial 3D scanning and reverse engineering through design refinement and production support, we manage each phase with precision and intent.

Our team brings deep, cross-disciplinary expertise across a wide range of manufacturing processes. Whether your project involves CNC machining, injection molding, composites, sheet metal, or other production methods, we apply the right engineering approach to deliver efficient, manufacturable solutions.