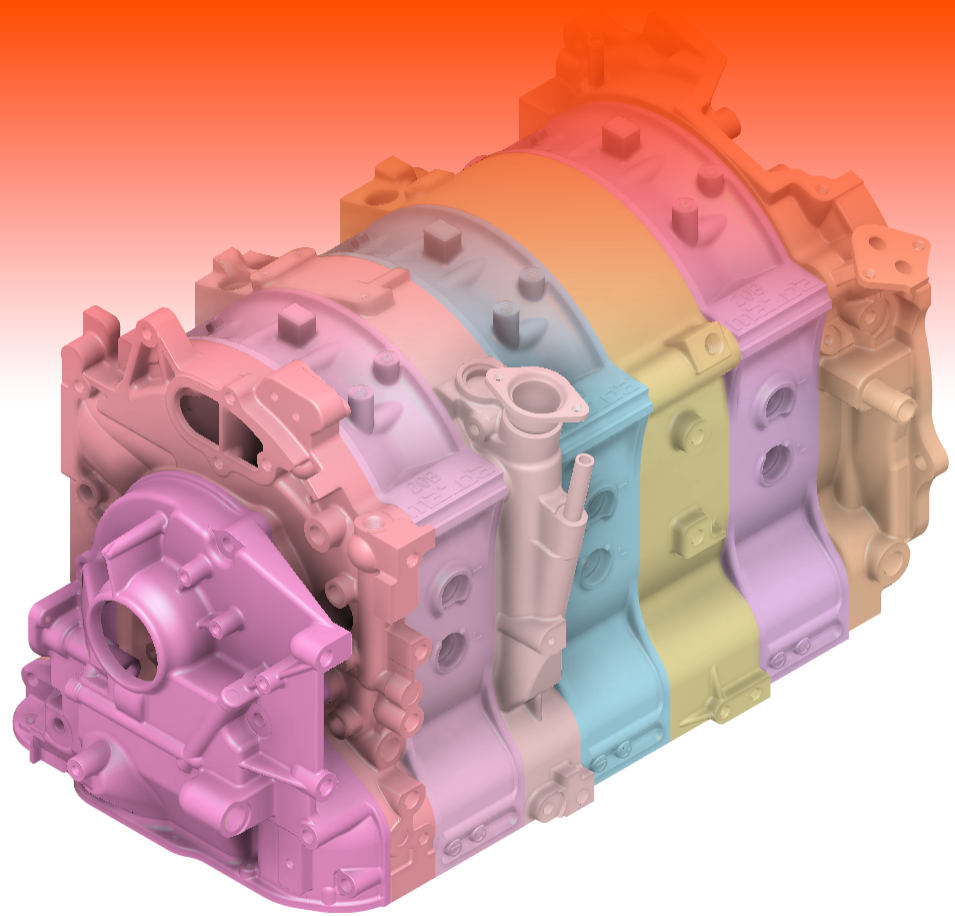

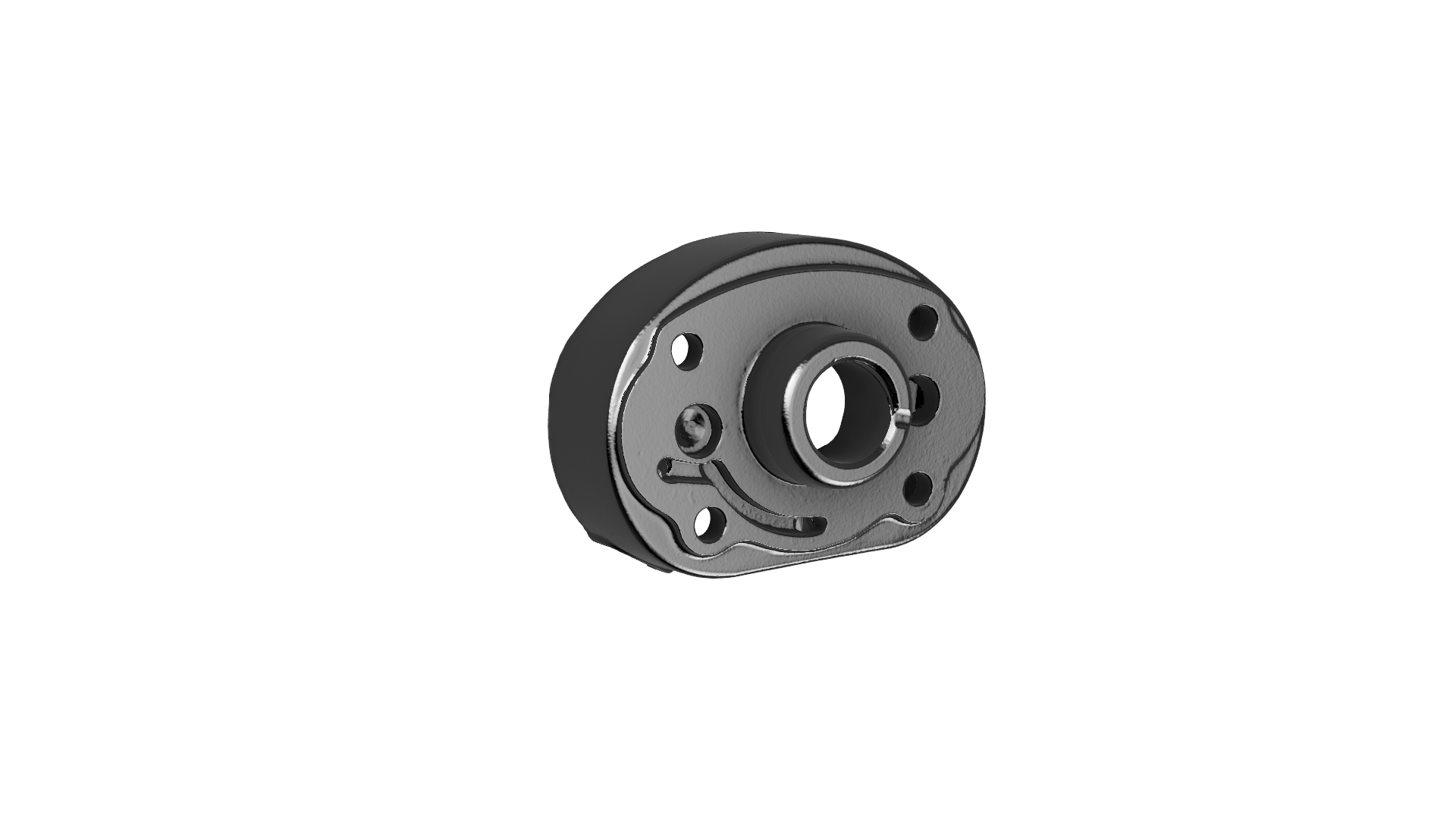

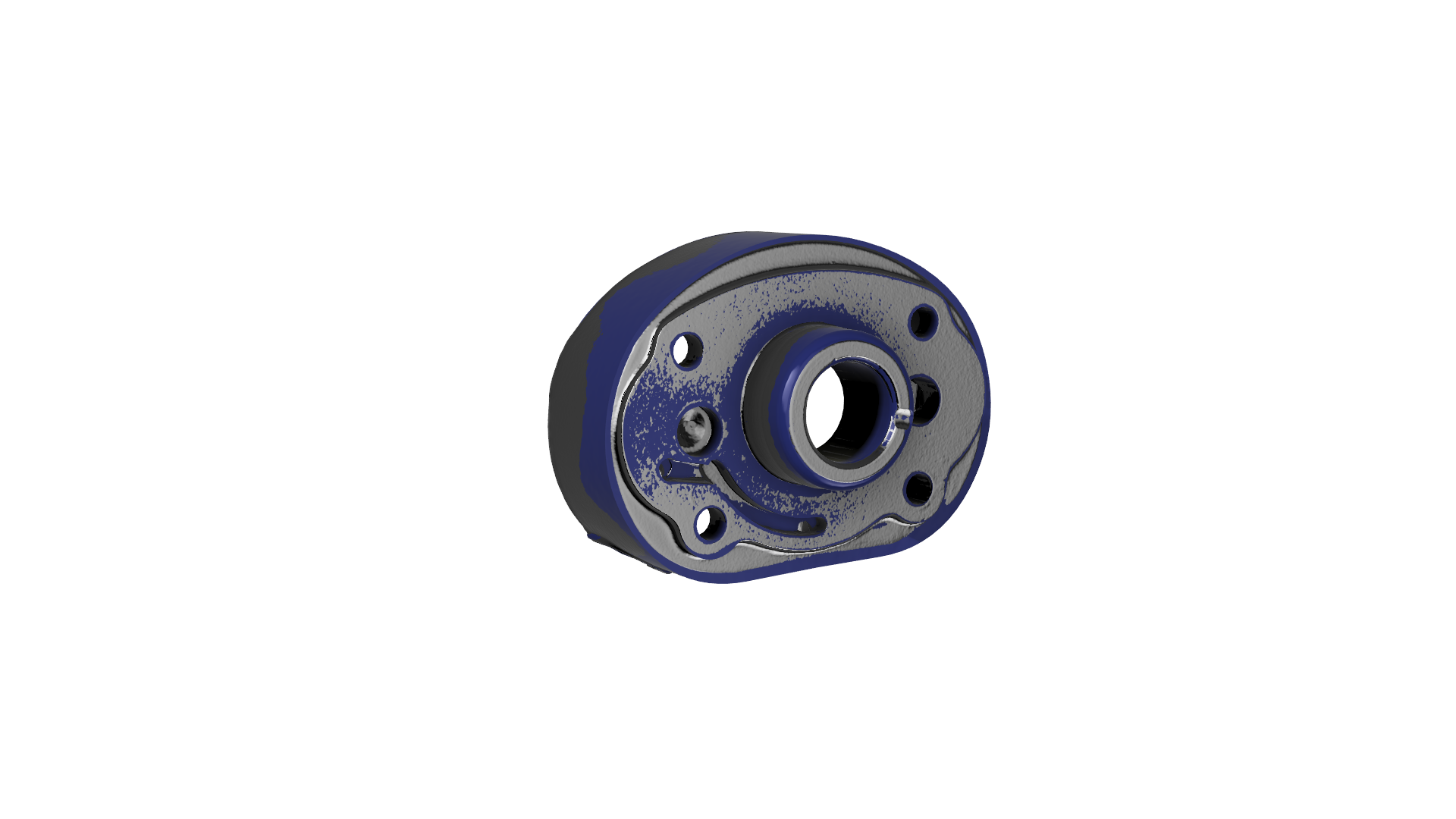

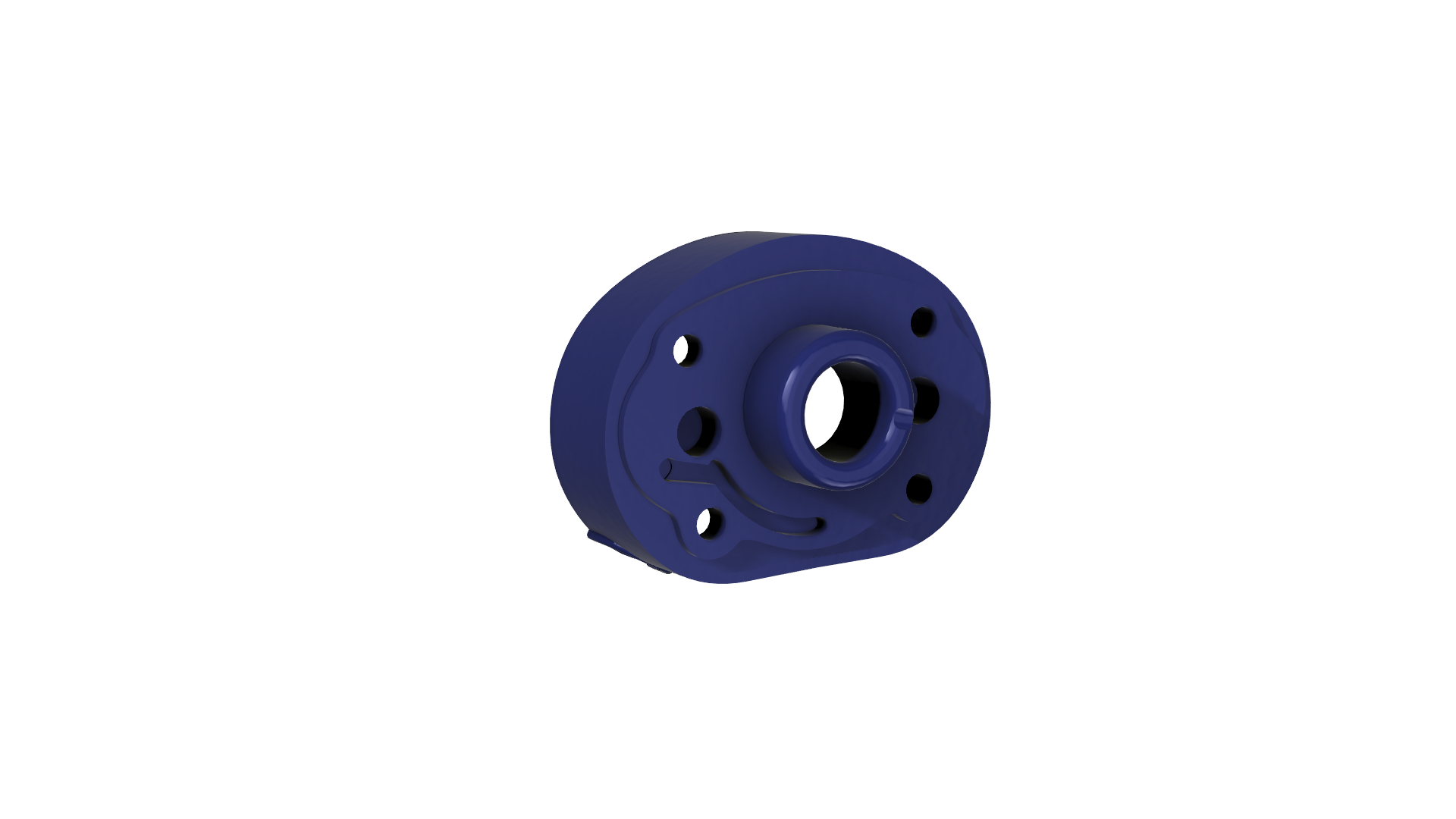

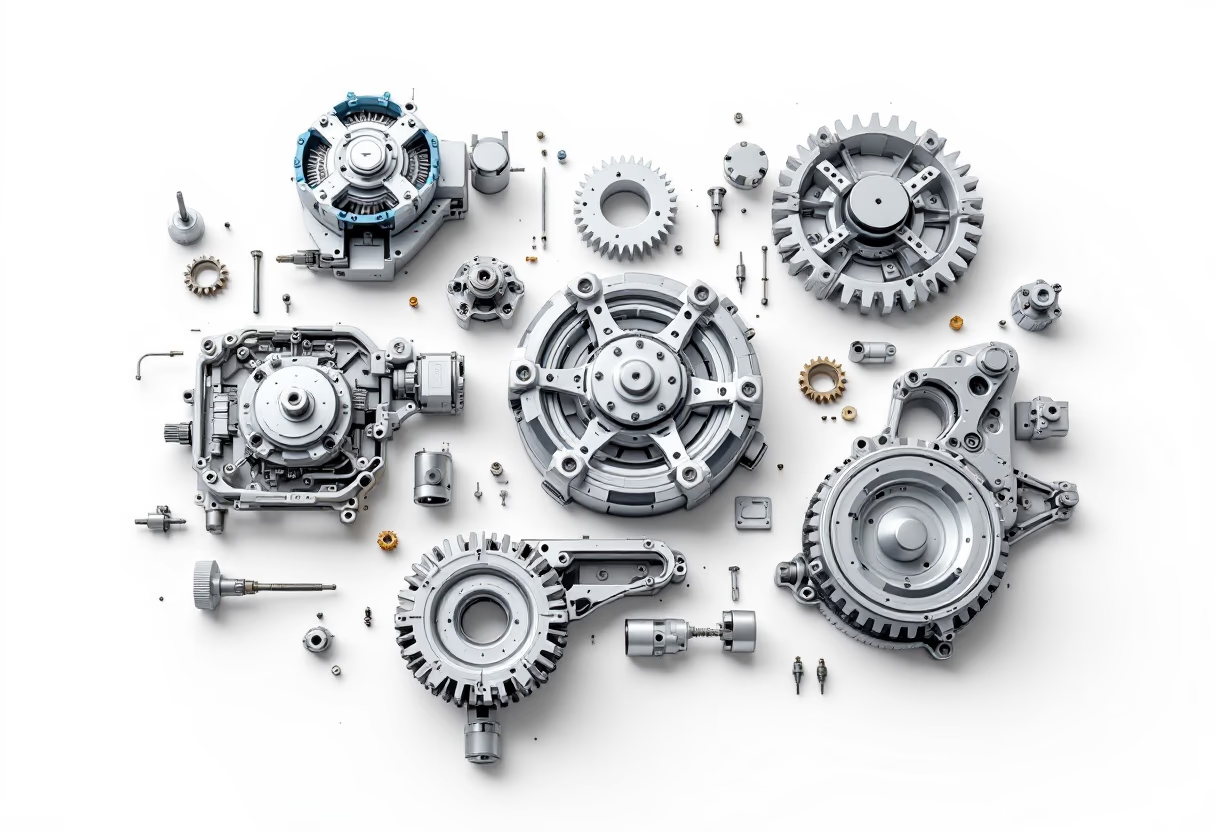

Accurate scans. Reliable engineering data.

High-precision 3D scanning, CAD validation, and quality verification for mechanical components. Supporting engineering teams with inspection, troubleshooting, and digital workflows for manufacturing and legacy parts.

![[background image] image of workspace setup (for a blockchain and cryptocurrency)](images/0f415234-15f9-4770-8ff1-49e1c9b11f89.avif)